Introduction

Tunnel Draft technology – also known as earth tubes or earth air tunnels or earth air heat ex-changers – have been around since the 1990’s in Europe and North America. The working principle has been the same since then[1].

Principal

Three to five meters below the ground the temperature is almost constant through-out the year at around 20 degrees Celsius. Heat travels from hotter to colder areas and hence when hot air comes into contact with colder earth here, it loses its heat to it and becomes cooler naturally. In this principal we are using earth as a giant, ever-lasting heat sink. The same logic works in reverse in the colder regions where the temperature below the earth is hotter than the outside. Simply speaking, this is why some polar animals take refuge in burrows made below the ground to keep themselves warm.

Design at Naandi

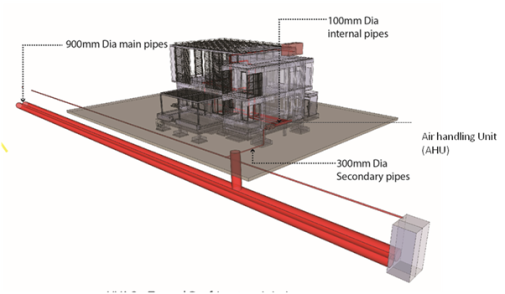

At Naandi – the Air handling units suck the outdoor air into the cement pipes (Hume pipes) in a ring main running around the entire layout which is underground at a depth of four meters or 12 feet. Outdoor air enters this ring main pipe through intake Orifices due to the static pressure created by the air handling unit. Air in this ring main travels long distance below the ground before entering the villa site through the 300 MM secondary pipe laid under the landscape. These 300 MM pipes are connected to a network of 100 MM pipes in the basement of each villa. Each of the 100 MM pipes will open as Air vents in all the rooms of the Naandi villa. That is, two openings in the living room, two for each of the three Bedrooms.

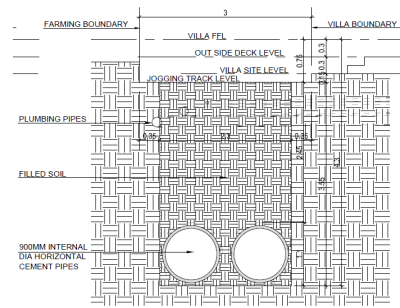

The Ring main pipe we are using at Naandi are 900 MM in diameter and are placed four meters below the ground level. The larger size of the pipes allows the air to come into contact with more surface area of the earth increasing the rate of heat transfer between the air in the pipe and the soil.

Due to their large size, the air flows over a larger surface area inside the pipes which will increase the rate of heat transfer between the pipe and the surrounding soil, resulting in the attainment of equilibrium low temperature condition faster.

The air handling units installed at each villa suck the air from the outdoors through the intake orifices that are strategically kept below Neem or other trees in the farm into the ring main hume pipes where the air loses its heat to the earth surrounding it. Thus cooled air is sent through a set of filters and pushed into the villa through the underground basement pipes (100 MM) which travel vertically up through the walls opening in each room as vents.

Our Innovation

The biggest hurdle in successfully implementing this technology was in analyzing the maintenance and water seepage issues it might pose and resolving them.

The biggest threat to the quality of fresh air from this system is the maintenance of these network of pipes and the water seepage issue is the central core of all the other threats that might arise. Below are the various ways in which these issues could occur and our preventive solutions for the same –

i) Rodents making holes in the pipes

Below is the sectional drawing of the Hume pipe system and it clearly shows that the depth of the pipes is 4 Meters or 12 feet. Rodents can burrow down only to a depth of about 1.5 m without serious injury[1] and hence these concrete pipes are unreachable to them. This depth automatically takes away the chances of any reptiles entering these pipes.

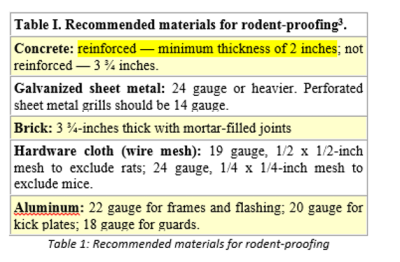

Also, the pipes being of cement concrete will further protect them from any such reptile or rodent attacks.

The hume pipes we are installing are of 100 MM thickness (that is 4 inches)

ii) Rusting and disintegrating of the pipes

Cement pipes have no issues of rusting. In fact, there are some piping systems in Australia which have been installed 90 years ago and are still running[1]. This is better than flexible pipes as flexible pipes are mostly dependent on soil support for strength, but hume pipes are rugged enough to take the wear and tear. Not only this, but due to their high conductivity, hume pipes create a perfect medium for heat transfer between air and the surrounding soil.

iii) Water seepage through the man holes

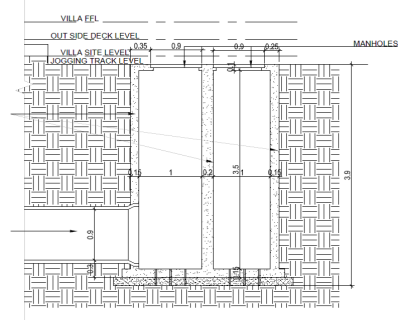

Our design of air-tight manholes leaves no room for water to enter into the pipes. Also, at every point where there are maintenance manholes, the design is as follows-

As in the above figure, the manhole cover rests on a platform that projects inwards while the cover is flushed to the jogging track level. The advantage of this sort of design is that, water invasion from the circumference of the man-hole is drastically minimized.

Also, the invert level of the pipe is 300 mm above the bottom of the man-hole. This means that even if water enters the manhole due to unforeseen reasons, it settles down and will not have any impact on the flow of air.

We take our design further than this to get rid of the water that has settled when the above situation occurs. They are what we call ‘weep holes’ at the base of the man hole which help in draining water into the ground or any condensed water vapour that may form in the pipe.

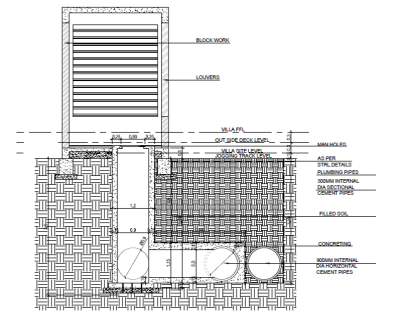

iv) Through the intake orifices

The intake orifices are designed as rooms with louvers on the side of the room that prevent any water from entering the room. The whole room is a solid block walled room with only the intake side with louvers which means there is also no chance water draining into the room from the outside.

V) Water entering through condensation

To prevent the condensate (water vapor) from forming water pockets and stagnating at any one point, all the buried pipes are sloped so that any water accumulated due to condensation flows towards the man-hole. As discussed in the above point, weep holes are provided here will drain the water into the ground. Weep-holes are also provided at regular intervals inside the pipes.

Vi) Formation of Mildew

Another issue that may arise in the pipes is the formation of mildew, this occurs with stagnant water. Once every year the maintenance of these pipes are to apply the interior of the pipes with anti-fungal paint which will keep this issue at bay.

The anti-fungal paint, Air handling Units with filters at every villa and providing manholes at regular intervals to carry out maintenance works are some of the design elements we have included apart from drawing out elaborate maintenance manual for the same. Underground surveying bots which can detect blockages would also be provided at the community. These bots can be used to figure what and where the problem inside the pipes and easily rectify them.

Ref: [1] “Use of Underground Air tunnels for Heating and Cooling agricultural and residential buildings” by D.Y.Goswami and K.M.Biseli, University of Florida (http://infohouse.p2ric.org/ref/08/07683.pdf)

[1] Concrete pipe facts, Concrete Pipe Association of Australasia (http://www.cpaa.asn.au/General/concrete-pipe-facts.html)

[1] Canadian Federation of Humane Societies – Mice and Rats (http://cfhs.ca/wild/mice_and_rats)